THE CMS ADVANTAGE

CONCRETE MANAGEMENT SYSTEM

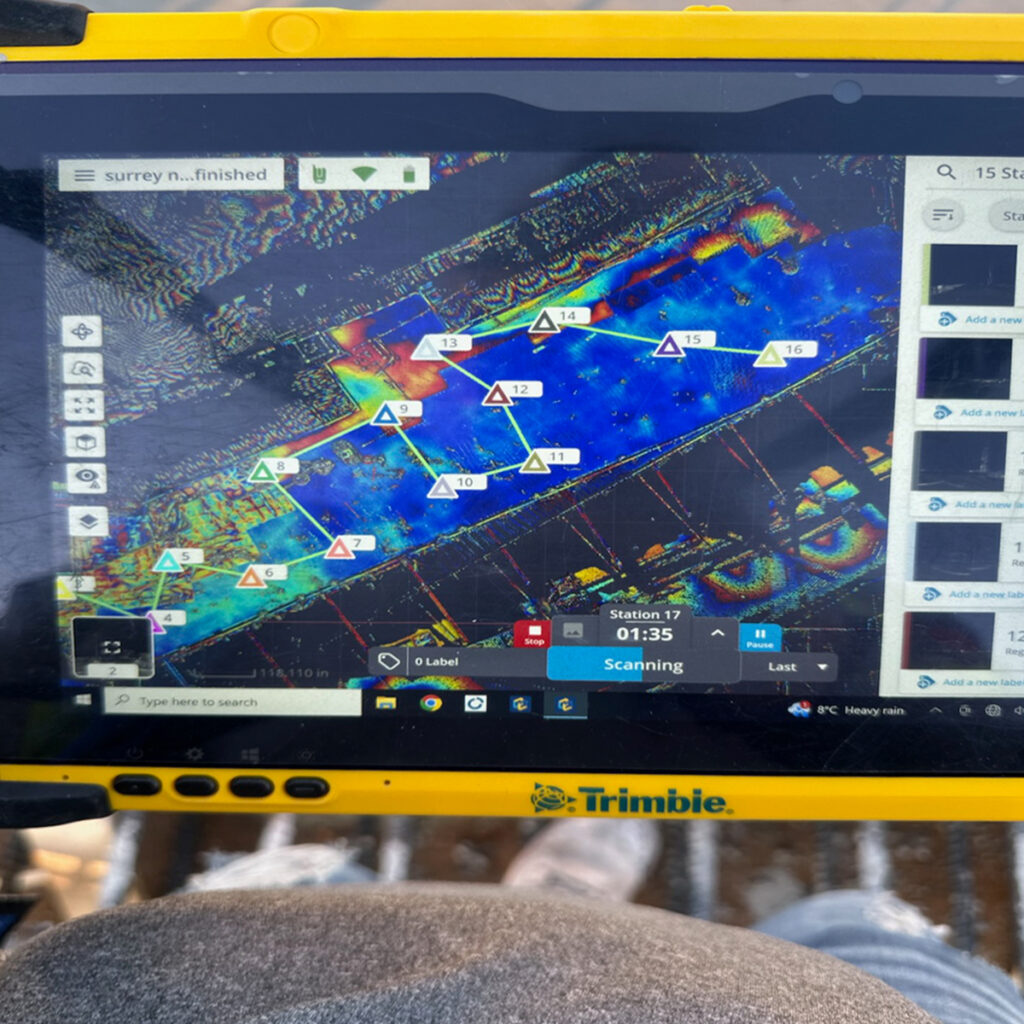

Wet concrete scanning using lidar technology

Revolutionizing Precision in Concrete Placing & Finishing

THE APPROACH

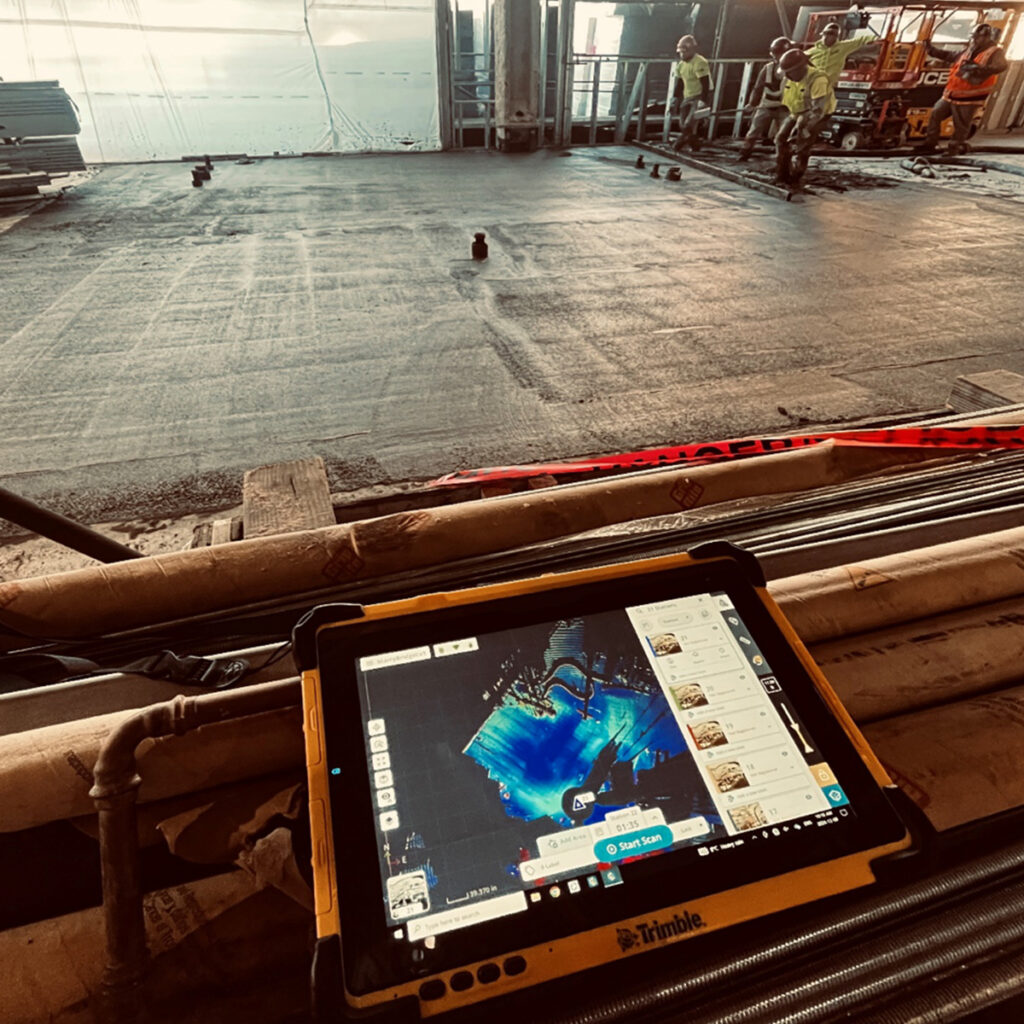

Our CMS wet scan involves capturing real-time Lidar scans of the concrete slab while it is still wet.

The process begins by positioning our equipment during the concrete pour and scanning areas as they are being worked on.

The process requires frequent scans to ensure that placers/finishers are nearby to address any discrepancies while the concrete remains workable.

Once the desired area is scanned, which typically takes about 90-120 seconds, we generate a registered point cloud heat map that will show on a tablet viewer for on-site analysis.

With the Heatmap function, a reference elevation is selected from the point cloud or a known elevation source. This elevation is what we are telling the program is the correct elevation of the slab. Adjustments are then made to colorize the point cloud based on specified elevation differences. This colorized representation facilitates the identification of areas requiring corrective action. The workflow is then repeated as additional areas are finished during the pour. This process offers several key advantages:

The Goal

Using technology to provide above average floor flatness from the start.

Technical Advantages of Concrete Management

The system scans the surface at thousands of data points per second, creating a 3D map/heat map of floors

Data can be used to create, cut and fill reports(?) for existing slabs.

These tools provide reports that can be used to measure material/labour consumption when correcting slabs.

Once corrections are made, we rescan and verify work is within compliance before moving on.

A Report is created and passed on to clients for records.

Identifies high and low spots, uneven slopes, and other irregularities with accuracy down to fractions of a millimeter.

Displays real-time surface data, enabling immediate analysis and decision-making.

Adjusts to project-specific requirements, ensuring compliance with architectural and engineering specifications.

CMS: TECHNOLOGY FORWARD

THE PROCESS

Initial Laser Scanning

The laser system captures comprehensive data on surface variations, including dips, ridges, and slopes, creating a detailed 3D map of the entire floor. This allows us to target problem areas with unmatched accuracy ensuring floors meet tolerances.

Whether it’s a new slab, a renovation, or a high-performance application, our laser mapping process guarantees a flawless foundation tailored to your project’s needs.

Latest technology

We use the latest technology adding our own programing to scan floors getting feedback in as little as 90 seconds.

Collect Information

The information gets passed on to crews placing which keep track to the work and make corrections as needed.

Precision Scan

We scan the slab several times ensuring that at each stage the floor maintains/improves the floor flatness tolerances.

Initial Scan

The initial scan happens at the placing of concrete including bull float. We provide accurate information to crews ensuring that they can meet and or exceed flatness specifications.

Final Scan

We scan the floor one last time once all power trowels have left the floor.

Generate Reporting

We then create a report to gets passed on to the client for review.

The report contains the following items:

- Weather conditions

- Concrete trucks arrival and departure

- Site conditions

- First scan FF report

- Second scan FF report

- Third scan FF repot

- Camber report

- Under slab bracing report

- Forming report

This process offers several key advantages:

1. Real-time Data Processing: Collecting of Site processes scans on-site. Providing instant feedback to construction teams and enabling immediate corrective action.

2. Enhanced Accuracy: By assessing concrete flatness and levelness during the pouring process, potential issues can be promptly identified and addressed. Minimizing rework and ensuring superior quality control.

Why Laser Concrete Mapping Is the Gold Standard

Laser Concrete Mapping represents the most innovative step in concrete preparation, offering unparalleled precision and efficiency. This technology reduces errors, streamlines workflows, and guarantees exceptional results, making it the gold standard for modern flooring systems.

PERFORMANCE & COST BENEFITS

Material Savings

Scanning greatly reduces levelling/floor prep, reducing costs and waste.

PERFORMANCE & COST BENEFITS

Time Efficiency

Accurate mapping shortens preparation times by eliminating unnecessary grinding and or levelling giving you back days on the schedule.

Enhanced Durability

A perfectly leveled surface reduces stress points, ensuring longer-lasting flooring systems.

Custom Solutions

Specifically tailored to meet and exceed project specifications and tolerances.

Error Elimination

Real-time data and post-prep verification ensure no surface irregularities go unnoticed.